Hydraulic Synchronous Lifting Jack System

SOV Hydraulic Technology (Shanghai) Co., Ltd.- Warranty:12 Months

- Type:Hydraulic Jack

- Structure:Hydraulic Jack

- Capacity (Load):up to 128, 000 Ton

- Power Source:Hydraulic

- Max Height:>400mm

Base Info

- Model NO.:SOV-PLC

- Certification:CE, ISO 9001:2008

- Condition:New

- Name:Hydraulic Synchronous Lifting Jack System

- Load Capacity:up to 128, 000 Ton

- System:Window Interface

- Function:Multi-Functions

- Control:Romote Control

- Voltage:220V-380V

- Computer Language:PLC

- Color:Yellow or Customized

- Lifting Type:4, 8, 16, 24, 64 Points

- Transport Package:Standard Export Wooden Case

- Specification:CE, ISO9001, SGS

- Trademark:SOV

- Origin:Shanghai, China

- HS Code:8425421000

- Production Capacity:60 Sets Per Month

Description

Basic Info.

Model NO. SOV-PLC Certification CE, ISO 9001:2008 Condition New Name Hydraulic Synchronous Lifting Jack System Load Capacity up to 128, 000 Ton System Window Interface Function Multi-Functions Control Romote Control Voltage 220V-380V Computer Language PLC Color Yellow or Customized Lifting Type 4, 8, 16, 24, 64 Points Transport Package Standard Export Wooden Case Specification CE, ISO9001, SGS Trademark SOV Origin Shanghai, China HS Code 8425421000 Production Capacity 60 Sets Per MonthProduct Description

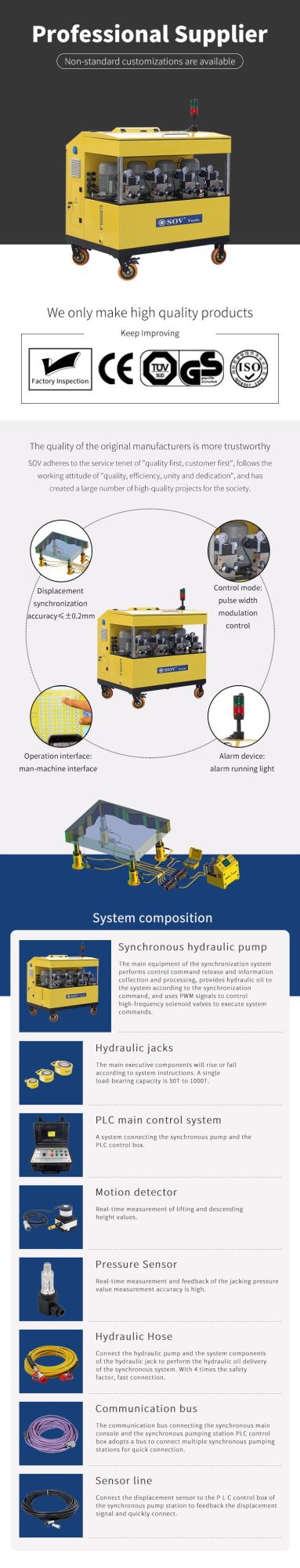

PLC synchronous lifting system according to the displacement, pressure sensor feedback to control a variety of large , heavy or complex movements to locate the structure , applicable to any component weight distribution. Synchronous Lift can reduce the jacking points between the curved or uneven weight distribution caused by load changes , distorted or tilted .

By a PLC controller monitors each jacking point displacement and load. By changing the flow rate of each hydraulic jacking point , the system can maintain a high-precision position control .

This displacement of the control system in the deviation of the load does not require human intervention to maintain the structural integrity , but also can improve the productivity and safety of the lifting operation .

Notable features:

1.A frequency control loop control , closed-loop control of pulse width modulation;

2.Pulse width modulation open - loop control technology to meet the different requirements of different users

3.( Or external ) displacement of two hydraulic cylinders built-in pressure sensors are loads jacking system to ensure reliability in harsh environments

are set to protect the cylinder valve function is not overloaded , the load balancing capabilities cylinder , so the cylinder does not load decline to loss of pressure decline

Up to advanced speed and heavy oil into the hydraulic circuit , not only when high-precision synchronous lifting at the same time ensure high accuracy load drop synchronization ,

4. the error does not exceed ± 0.5mm

5.speed set to zero, low- jacking , lifting speed can be controlled

6.Color touch screen , the implementation of online display jacking displacement , lifting loads and other states , can also be mounted IPC implementation record the whole construction process

7.Common PLC four points synchronous lifting , also expandable to 24 points or 32 points or more multi-point synchronization , multi-point synchronization in addition to maintaining the state of multi- point synchronization , the user's requirements and in accordance with the mediation of the pivot load distribution

Parameter

| Model | Points Number | Synchronous Precision(mm) | Motor Power(Kw) | Voltage (V) | Pressure (MPa) | Flow (L/min) | Oil Tank (L) |

| SOV- DMTB-4 | 4 | <=+-0.5 | 2.2 | 380 | 70 | 2 | 130 |

| SOV- DMTB-8 | 8 | <=+-0.5 | 2.2 | 380 | 70 | 2 | 130 |

| SOV- DMTB-12 | 12 | <=+-0.5 | 2.2 | 380 | 70 | 2 | 130 |

| SOV- DMTB-16 | 16 | <=+-0.5 | 5.5 | 380 | 70 | 5 | 200 |

| SOV- DMTB-24 | 24 | <=+-0.5 | 5.5 | 380 | 70 | 5 | 200 |

Photos

Applications:

1. For synchronous lifting and load positioning applications

2. large, heavy objects weighing, moving synchronous lifting (lifting )

3. heavy equipment when lifting and lowering installation and maintenance

4. highway bridge maintenance and replacement of rubber bearings Jacking

5. highway, railway overpass overall elevation

6. buildings jacking and translation

7. heavy load , pile structural testing

8. With the support and promotion of leveling existing buildings

9. bridge lifting and repositioning

10. levels of load moving

11. synchronous pressure Hull jacking

Certificate